5G Aluminum Die-Cast Radiator | Extended Low-Band Solution

While most 5G aluminum die-cast radiators operate within limited bands (698–960 MHz), RF element engineers have pioneered an industry-first extended low-band radiator covering 617–960 MHz. This breakthrough addresses critical gaps in global 5G/4G deployments, enabling seamless connectivity for rural networks, underground facilities, and IoT ecosystems where low-frequency penetration is paramount.

Technical Innovation: Engineering the Impossible

1. Ultra-Wideband Performance

| Parameter | Standard Radiators | RF Element’s Solution |

|---|---|---|

| Frequency Range | 698–960 MHz | 617–960 MHz |

| Bandwidth Coverage | 262 MHz | 343 MHz (+31%) |

| VSWR | ≤1.8:1 | ≤1.5:1 |

| PIM (2x20W) | -150 dBc | <-155 dBc |

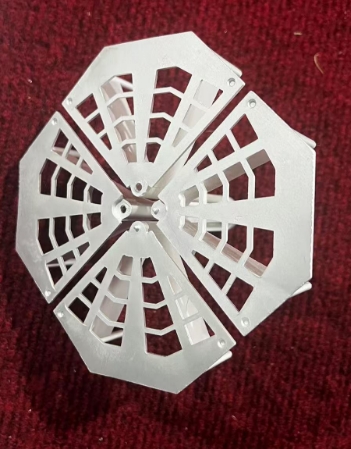

Achieved through proprietary dipole arm geometry and impedance-matching slots.

2. Precision Manufacturing Process

a) Mold Design Innovation

Multi-stage CFD simulation for molten aluminum flow optimization

Conformal cooling channels ensuring ±0.05mm dimensional stability

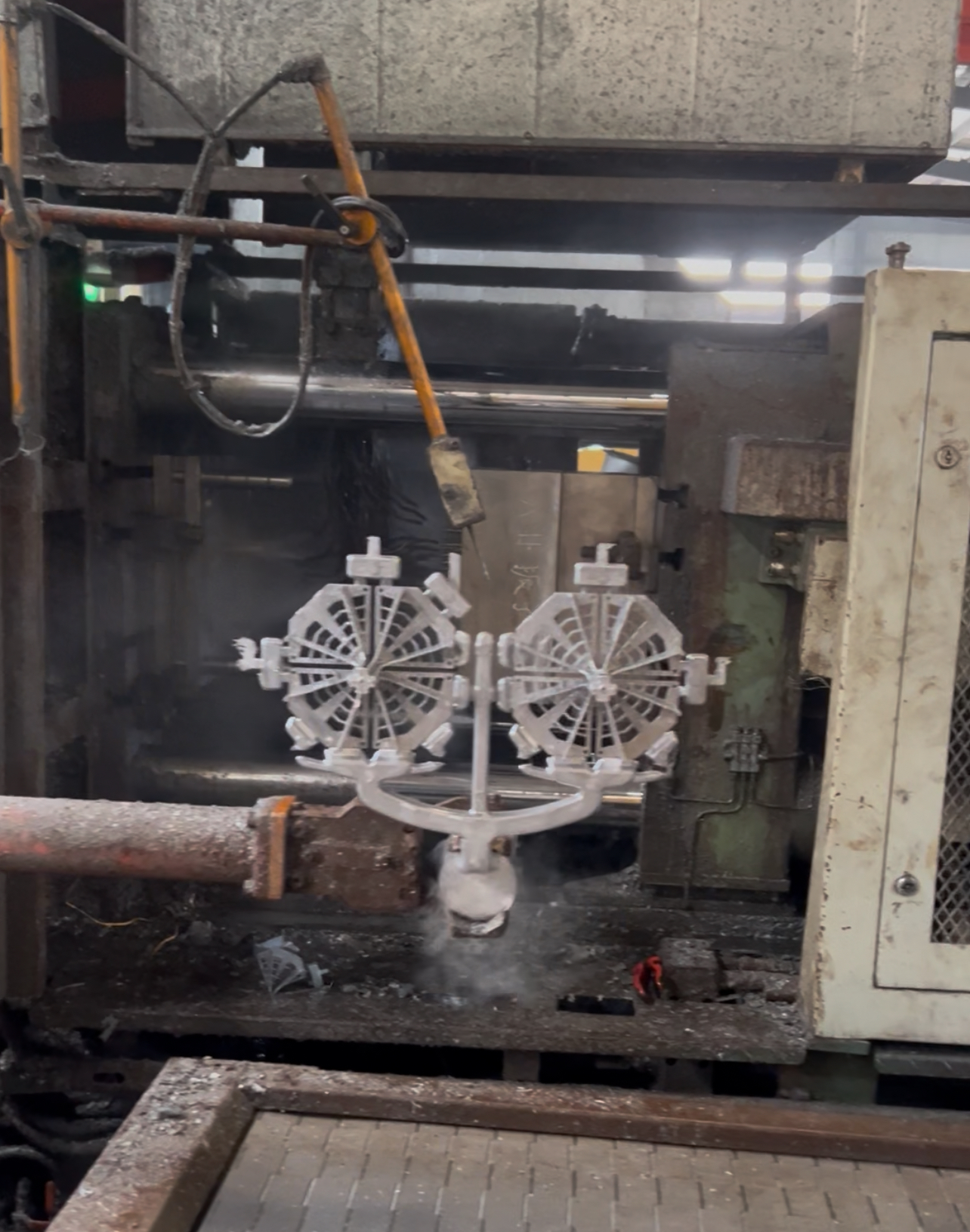

b) Die-Casting Excellence

800-ton pressure injection at 720°C

Vacuum-assisted pores elimination (<0.2% porosity)

c) Surface Engineering

Electroplating: 8μm nickel undercoat + 3μm silver finish for oxidation resistance

Micro-Sandblasting: Ra 1.6μm surface roughness enhancing radiation efficiency

Why 617 MHz Matters for Global Networks

Critical Applications Enabled

| Region/System | Band | Use Case |

|---|---|---|

| North America | n71 (617–698 MHz) | Rural 5G coverage |

| Public Safety | Band 14 (700 MHz) | FirstNet emergency networks |

| Europe | n28 (703–748 MHz) | Subterranean mining comms |

| Global IoT | LTE-M/NB-IoT | Massive sensor deployments |

Quality Validation: Beyond Industry Standards

Rigorous Testing Protocol

Electrical Performance

Anechoic chamber radiation pattern validation (SATIMO StarLab)

PIM testing @ 2x40W (Kaelus iPA-40)

Environmental Durability

500hr salt spray (ASTM B117)

Thermal cycling (-40°C ↔ +85°C, 200 cycles)

5G vibration profile (3–500Hz, 3hrs)

Field Results

12-month deployment in Canadian Arctic mines: 0 radiator failures

Signal penetration gain: +5.2dB vs competitors at 650MHz

Technical Specifications

| Model | RFE-LBR-617/960 |

|---|---|

| Frequency Range | 617–960 MHz |

| Gain | 4.5–6.2 dBi (band-optimized) |

| Polarization | Vertical / ±45° |

| Power Handling | 300W peak |

| Material | ADC12 aluminum alloy |

| Surface Finish | Ni+Ag plating (IEC 60068) |

| Weight | 280g ±5g |

Case Study: Australian Outback Network Expansion

A telecom carrier deployed RF Element’s radiators in n28 band (700MHz) antennas across 150 remote sites:

Coverage Radius: Extended from 18km → 24km

Signal Penetration: 35% improvement in steel-reinforced buildings

OPEX Savings: Reduced tower sites by 22%

Why Engineers Choose RF element

End-to-End Control

"Our vertically integrated process – from mold design to final plating – eliminates supply chain variables. Each radiator ships with a 3D radiation pattern report."

Dr. Chen, RF element Lead Antenna Designer

Certifications

ISO 9001:2015 manufacturing

RoHS/REACH compliant

GR-487 telecom reliability standard

RF element’s 617–960 MHz aluminum die-cast radiators solve the most challenging connectivity gaps with uncompromised quality. By mastering every production stage – precision die-casting, electromagnetic optimization, and military-grade surface treatment – we deliver radiators that outperform industry standards where signal integrity matters most.

TAG:5G Aluminum Die-Cast Radiator | Extended Low-Band Solution https://www.rfelement.com