Directional panel antennas are key players in keeping our signals strong and clear over long distances. They're reliable and efficient, but with some extra steps after they're made, we can make them even better. In this article, we'll look at how sandblasting and oxidation can help improve these antennas.

What are Directional Panel Antennas?

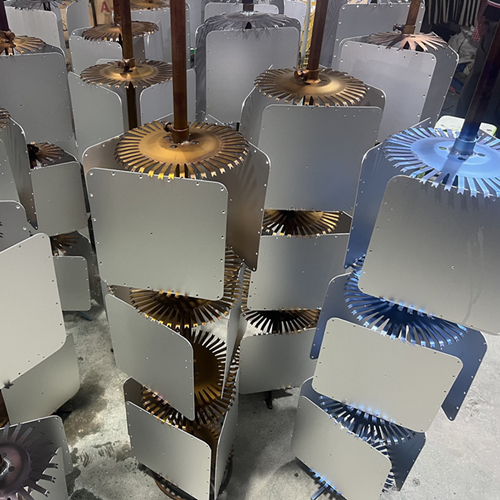

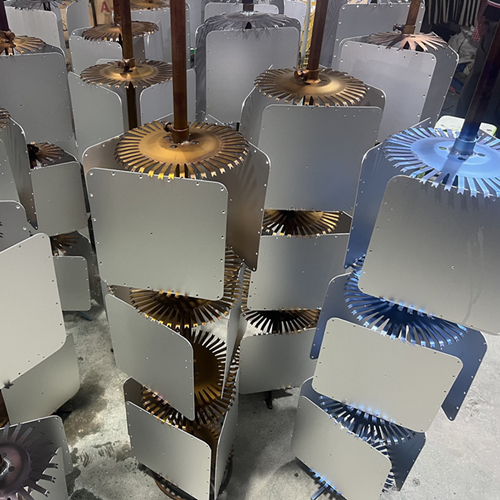

These antennas send and receive signals in a specific direction, making them perfect for direct communications. They're flat and rectangular, with parts arranged in a grid. This design helps focus the signal, reduce interference, and boost strength and range.

The Role of Post-Processing

The way we make these antennas is important, but what we do after can also make a big difference. Two main ways we improve them are sandblasting and oxidation.

Sandblasting: A Precise Process

Sandblasting is where we blast the antenna's surface with tiny particles to remove dirt and create a certain texture. This can help in a few ways:

Cleanliness: It gets rid of things like rust and grease, keeping the signal clear.

Texture: We can change the texture by adjusting the pressure and particles, which helps with how the signal reflects.

Sticking Power: The rough surface helps coatings stick better.

Oxidation: Making it Last

Oxidation is where we expose the antenna to oxygen or something that makes it react. This can be done in different ways and has several benefits:

Corrosion Resistance: It creates a layer that protects the antenna from rust and damage.

Durability: The layer makes the antenna stronger and longer-lasting.

Signal Quality: It can also make the antenna work better electrically, reducing interference.

Using Sandblasting and Oxidation in Antenna Production

We use these techniques at different stages of making the antennas:

Prep Work: We sandblast parts before putting them together to get rid of dirt.

Texture Control: During production, we can sandblast certain areas to improve how the signal reflects.

Final Treatment: After the antenna is together, we use oxidation to make it tougher.

Customization: We can adjust how much we sandblast and oxidize to fit different antenna needs.

Real-World Example

Let's look at a real-life example. We had directional panel antennas in a coastal area where they were facing saltwater and humidity.

Challenge: The antennas were rusting and the signal was getting worse.

Solution: We sanded the parts before installing them and added an oxidation layer to protect them.

Results: This combo kept the antennas working longer, saving on maintenance and keeping the connection steady.

By using sandblasting and oxidation, we can make directional panel antennas even more effective. These techniques clean the surface, control texture, fight corrosion, and improve durability. As we keep improving our tech, these methods will be key to making our antennas better and keeping our communications strong, even in tough spots.

TAG:Enhancing Directional Panel Antennas through Sandblasting and Oxidation Post-Processing https://www.rfelement.com