5G Antenna Manufacturer: Mastering Aluminum Die-Cast Radiators from Concept to Production- Our Technological Leaps

For any 5G antenna manufacturer, the radiator is the component that ultimately determines signal integrity, power handling, and long-term reliability. While PCB radiators dominate high-volume indoor applications, aluminum alloy die-cast radiators remain the preferred choice for high-power outdoor base stations, macro cells, and mission-critical infrastructure where thermal management and structural robustness are paramount.-

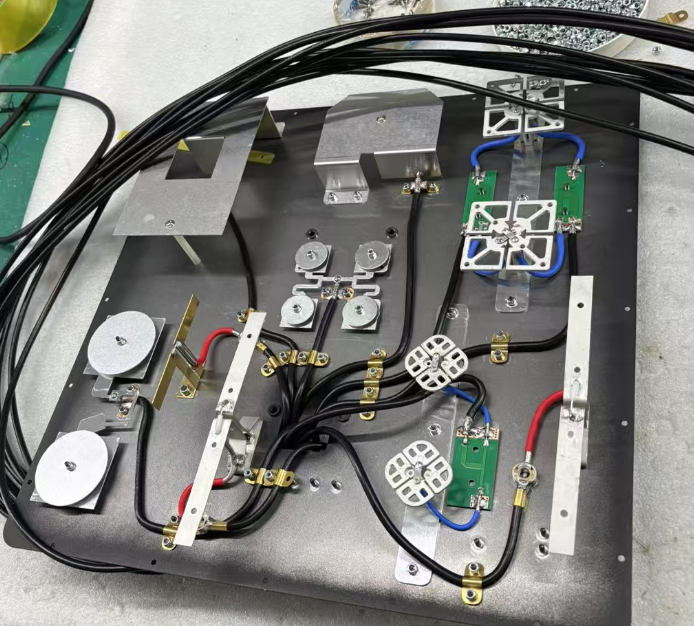

At RF element, we have developed a vertically integrated engineering and production capability for aluminum die-cast radiators. From initial electromagnetic analysis through mold design, precision casting, and final surface treatment, we control every variable to deliver radiators that outperform industry standards..

The RF element Approach: End-to-End Radiator Development

Phase 1: Electromagnetic Analysis & Structural Design

Every radiator project begins with rigorous electromagnetic simulation. Our engineers use CST Microwave Studio and HFSS to model current distribution, impedance matching, and radiation patterns before a single mold is cut.

Key design considerations:

Dipole arm geometry: Proprietary shapes optimized for bandwidth and gain flatness

Impedance-matching slots: Precision-engineered to achieve VSWR <1.5:1 across target bands

Thermal paths: Integrated heat dissipation channels for high-power operation (300W+ peak) -

For extended low-band applications (617–960 MHz), our patented dipole arm designs deliver +31% bandwidth coverage compared to conventional radiators, critical for n71/n28 global deployments.

Phase 2: Mold Engineering & Simulation

Die-casting mold design determines final radiator precision and consistency. Our tooling team employs:

Multi-stage CFD simulation: Modeling molten aluminum flow at 720°C to optimize fill patterns and eliminate air entrapment3

Conformal cooling channels: Maintaining ±0.05mm dimensional stability across thousands of production cycles

H13 tool steel cores with XR-D coatings (2–5μm thickness) for extended mold life and oxidation resistance1

Mold validation includes thermal imaging during first articles to ensure uniform cooling—critical for preventing internal porosity and ensuring consistent RF performance.

Phase 3: Precision Die-Casting

Our production floor operates 800-ton pressure injection machines capable of producing complex thin-walled radiators with:

Vacuum-assisted die-casting: Reducing porosity to <0.2% for superior electrical conductivity

ADC12 aluminum alloy: Chosen for its excellent castability, strength, and thermal conductivity (96 W/m·K) -3

5Automated extraction: Minimizing handling distortion and ensuring repeatability

Each production lot undergoes first-article dimensional inspection via CMM (coordinate measuring machine) before full production release.

Phase 4: Surface Engineering

Raw aluminum radiators require specialized surface treatment to ensure long-term reliability and RF performance:

| Treatment | Specification | Benefit |

|---|---|---|

| Nickel undercoat | 8μm thickness | Corrosion barrier, adhesion layer |

| Silver plating | 3μm thickness | Superior conductivity, PIM < -155 dBc - - |

| Micro-sandblasting | Ra 1.6μm surface | Enhances radiation efficiency - |

These treatments undergo 500-hour salt spray testing (ASTM B117) and thermal cycling from -40°C to +85°C to validate durability in extreme environments.

Phase 5: Validation & Quality Assurance

Every radiator design must pass our multi-stage validation protocol before customer shipment:

Anechoic chamber testing: SATIMO StarLab system measuring 3D radiation patterns, gain flatness, and beamwidth accuracy

PIM testing: Kaelus iPA-40 at 2×40W confirming <-155 dBc performance -

Mechanical verification: Pull-testing of mounting features, vibration profiling (3–500Hz, 3hrs)

Batch sampling: Ongoing statistical process control monitoring dimensional and electrical consistency

Case Study: Extended Low-Band Radiator for North American n71 Deployment

A major US telecom operator required a 617–960 MHz radiator capable of surviving harsh outdoor environments while maintaining ultra-low PIM.

RF element solution:

Custom die-cast ADC12 radiator with optimized dipole geometry

800-ton vacuum-assisted casting for <0.2% porosity

Ni+Ag plating with micro-sandblasted surface

Results after 12-month field deployment in Canadian Arctic mines -

Zero radiator failures across 1,200+ units

+5.2dB signal penetration gain at 650MHz vs. competitor designs

Coverage radius extended from 18km to 24km in Australian outback deployment

Why RF element for Aluminum Die-Cast Radiators?

| Capability | RF element Advantage |

|---|---|

| Material Science | ADC12 alloys optimized for strength + thermal conductivity |

| Simulation | Full-wave EM + CFD flow analysis before mold commit |

| Precision | ±0.05mm dimensional control via conformal cooling |

| Surface Engineering | In-house Ni+Ag plating, micro-sandblasting |

| Validation | 100% anechoic + PIM testing, 500hr salt spray qualified |

| Certifications | ISO 9001, RoHS, REACH, GR-487 |

As a specialized 5G antenna manufacturer, RF element brings together deep electromagnetic expertise and full-spectrum die-casting capability. Whether you need a custom low-band radiator for n71/n28 applications, a high-gain array element for massive MIMO, or a ruggedized design for extreme environments, our team delivers—from first analysis to volume production.

TAG:5G Antenna Manufacturer: Mastering Aluminum Die-Cast Radiators from Concept to Production https://www.rfelement.com